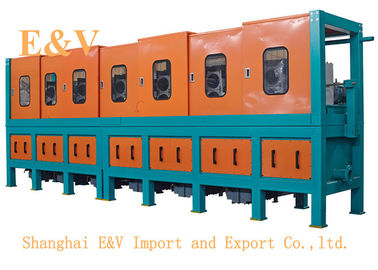

Copper alloy rod rolling mill

I. major information

Mechanical design uses advanced crafts and high-quality materials, such as roller; the appearance of the machine adopts German design,which has higher work efficiency than other similar products;Electrical parts assemble the imported parts from Japan, which have safe and reliable performance, high technological content; the whole production process is monitored by color touch screen with clear data displaying, easy operating and high automaticity. 2 high motive power frame copper rod rolling mill is beautiful, efficient and durable.

II. Advantage of 2 high cold rolling mill

Rollers of each rolling stand are driven by separate inverter motor. When the shape of the pass and rotating speed of each pass stand roller are changed at the same time, each stand can operate asynchronously. Processing rollers can change the shape of the pass, and the gear ratio of each stand roller can be set on the touch screen. So on the premise of meeting the stand strength, 2-roller copper rod cold rolling mill can roll different dimensions of copper rod and also roll other materials.

III.Main Data

Model: Copper rod cold rolling mill, copper alloy cold rolling mill. Other metal rod cold rolling mill, other alloy cold rolling mill,copper / aluminum continuous casting and rolling etc.

2 Input dia Ф55mm,Ф35mm,Ф25mm,Ф20mm,Ф17mm,Ф16mm,Ф14.4mm,Ф12.5mm,Ф8mm etc.

3 Output dia Ф20mm,Ф18mm,Ф17mm,Ф8mm,Ф6mm,Ф5mm,Ф4mm,Ф3 mm etc.

4 Outlet rod out of roundness No more than 0.2mm after rolling, or more accurate

5 Rolling pass 2-16 or as each customer’s requirements

6 Rolling speed Max 3M/s for continuous rolling, Max 5M/s for discontinuous rolling.

7 Pass schedule ellipse-round hole type system or triangular -round type system

8 total extend compression ratio 2-10, or as each customer’s requirements

9 each pass compression ratio 1.15~1.4(hole type can change)

10 Total power 100kw~500kw

11 Running mode Each frame separate transmission speed controlled by frequency or AC servo

12 Operation mode PLC control, touch screen display,can improve to DCS control or networking

13 type 2 high horizontal- vertical or 3 high positive triangle-inverted triangle

14 nominal roller dia

IV.Main component

1. Rolling mill base 2. 2-roller motive power frame(including reducer, Inverter motor) 3. Pay-off frame 4. coiling take-up system 5. Lubrication system 6. Emulsion system 7. Electronic control system 8.straightening device

1) main rolling mill

The main rolling mill is the important part of the continuous cold rolling mill . It includes base, frame, reducer, motor etc.

2)guide system

each pass has entry and exit guide, odd frame of entry guide glides to lead in, and even frame rolls to lead in.

3)pay off

3.1 max dia : Φ1600mm

3.2 max load capacity :3t

4)Coiling take-up machine

This machine consists of draught gear and take-up device, meets the characteristics of taking-up enclosure and requirements of constant taking-up speed.

5)Oil lubrication system

Oil flows through pump to filter, passes roll organization and oil tube of the main reduction box ,then flows through branch oil tube, bearing to spray oil lubrication.

6)Emulsion system

In order to improve the surface quality of the cold rolling copper rod, emulsion cool and lubricate the roller , copper rod and guide device in the rolling process.

7) electrical system

The electrical system includes the power system and the controlling system.

8 )feeding and straightening device

The feeding and straightening device is in front of the main rolling mill

55mm, 35mm, 25mm, 20mm, 17mm, 16mm, 14.4mm, 12.5mm, 8mm

20mm,18mm, 17mm, 8mm, 6mm, 5mm, 4mm, 3mm

Dear friends,

welcome to contact with us!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!